Add:Shang Wang Linxi Industrial Zone, Ruian, Zhejiang

Tel:+86-577-65161186

Phone:+86-13868824490

Fax:+86-577-65161187

Post code:325200

Website:www.chinazhenbang.com

Email:jessiepan@chinazhenbang.com

zb@chinazhenbang.com

Full servo eight color petal flexography printing machine

1、 Basic characteristics

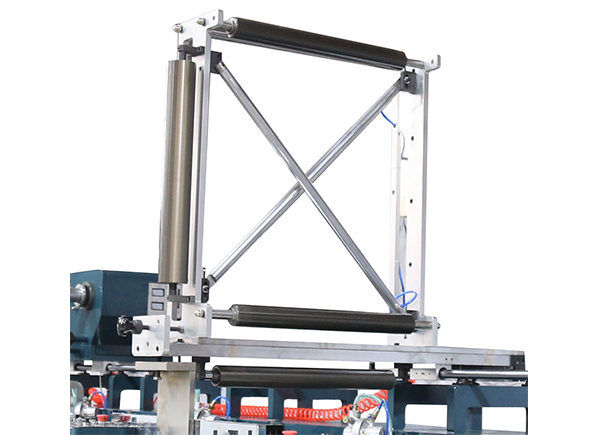

1. Unwinding unit

Unwinding air brake+electrical proportional valve+automatic constant tension control system

Hydraulic loading and unloading

Paper break stop device

Equipped with an inflatable gun

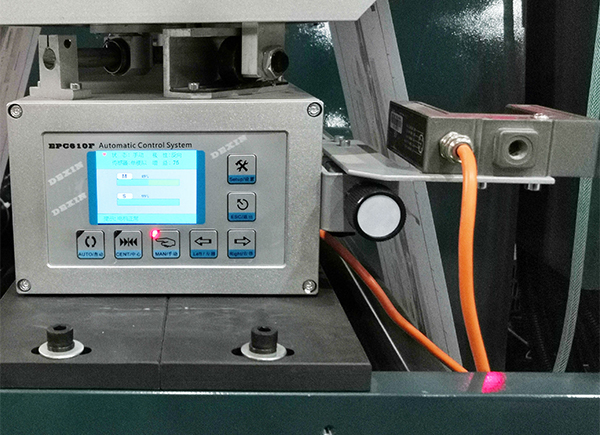

2. Automatic deviation correction system

Equipped with a paper receiving desk

The paper guide roller adopts high hardness anodizing treatment

Adopting ball screw electric actuator

Using ultrasonic sensors for deviation correction transmission induction

When there is a slight deviation during the movement of the paper web, the system can continuously and accurately correct it

Detection method: edge detection

Deviation correction accuracy: ± 0.12mm

3. Paper inlet/outlet system

Double pressure rubber roller combined pressure paper feeding

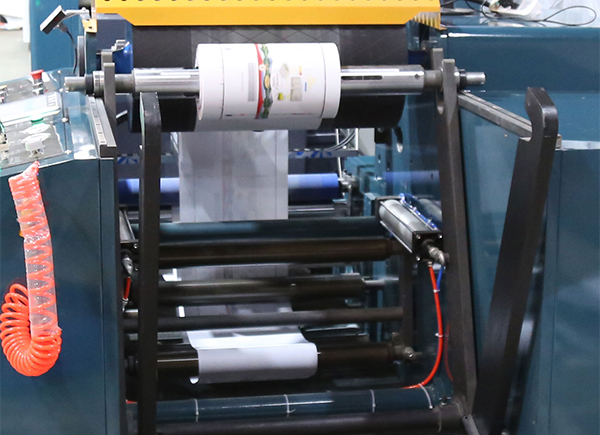

4. Printing color group

Pneumatic clutch pressure of mesh roller and plate roller

Ceramic wire roller, 1 color and 1 piece (determined by the customer)

Aluminum plate roller, 1 color and 2 strips (the number of teeth is determined by the customer)

If the mesh roller and ink scraper are replaced, there is no need to readjust the pressure

Stainless steel ink cartridge

Stable pressure of the plate roller and fast roll changing

Automatic cleaning of the printing plate function: After each shutdown, the mesh roller is released from the pressure, and the plate roller continues to rotate for 1.5 seconds to transfer the ink on the printing plate to the paper, keeping the printing plate clean.

• Web roller rotation function: Each time the machine is stopped, the web roller will automatically operate to prevent ink from drying and solidifying on the surface of the web roller, causing mesh hole blockage.

Three roller gear: cp1/8, made of 20CrMnTi material, with high wear resistance and long service life

Full runout of mesh roller, plate roller, and bottom roller: ≤ 0.03mm

5. Drying system

Heating and drying of infrared short wave IR lamp tubes in the printing unit

Printing unit natural air blowing combination (including extraction and blowing fan), with adjustable intake and exhaust air volume

External closed air intake and exhaust integrated electric heating and drying oven for printing unit (high-speed startup as supplementary heat source)

6. Synchronous stroboscopic color detection unit

Real time image capture and detection of printed materials during the printing process, allowing for lateral movement from left to right

The detection position can be set horizontally and vertically

Able to zoom in on the detection image, locate and observe it

7. Winding unit

• Roll back center surface roll up

Hydraulic loading and unloading

Equipped with an inflatable gun

8. Automatic shutdown function for preset production completion

9. Can achieve multi-point speed regulation function

10. Touch screen control

11. Automatic pasting machine

technical parameter

Printing speed 10-150 meters/minute

Effective printing width: 650mm

Effective printing perimeter: 247.5-800mm

Positioning accuracy: ± 0.15mm

Unwinding diameter: 1200mm Unwinding diameter: 1200mm